DUAL PINION DRIVE TURNTABLE

Case Study

PROBLEM:

Our client required a cost effective solution for their self-driving car calibration system. The solution needed to integrate with an existing CUSA 55SSV turntable that had been in operation for some time, ultimately streamlining their workflow.

SOLUTION:

Carousel USA engineers developed an innovative dual-gearbox system, featuring two pinion gears preloaded in opposing directions to effectively eliminate backlash within the mechanical system. This advanced drive solution incorporates a Nord AC motor, mechanically coupled to two high-performance German-engineered gearboxes from Stober through a third hypoid gearbox, ensuring exceptional reliability.

Figure 1:

Gearbox system and Stober Gearboxes fastened to a machined base plate for precision axial alignment of input shafts

FEATURES & SPECIFICATIONS:

- Dual Pinion Drive Turntable Velocity: 5-10°/sec

- Positional Accuracy: 0.1°

- Positional Precision: 0.01°

- Load Capacity: 1,000 lbs. Distributed

- Turntable Slip Ring: 1GB/s Data Transfer Rate

- Controls: CUSA MC3 Motion Control UL508A Approved

DEFINITIONS:

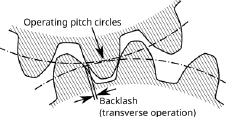

Backlash: sometimes called lash or play, is clearance between mating components, sometimes described as the amount of lost motion due to clearance or slackness when movement is reversed, and contact is reestablished. For example, in a pair of gears, backlash is the amount of clearance between mated gear teeth.

Figure 2: Diagram illustrating how backlash works in a gear drive system

Figure 1:

Gearbox system and Stober Gearboxes fastened to a machined base plate for precision axial alignment of input shafts

POSITIONAL PRECISION VS ACCURACY:

Accuracy refers to how close the platform’s actual position is to the desired or target position from its previous position. If the platform reaches the correct position as intended, it’s accurate.

Precision refers to the consistency of the platform’s over multiple

attempts. If the platform consistently reaches the same position each time, even if it’s slightly off from the desired position, it’s precise.

DESIGN PROCESS:

The drive system was entirely designed in-house using SolidWorks 3D CAD software. With decades of experience in mechanical design, FEA, drafting, and geometric dimensioning and tolerancing (GD&T), our engineering team brings a wealth of expertise to every project. Leveraging our extensive knowledge of the turntable industry, we developed the system from the ground up, applying proven gear drive design principles. Our staff carefully reviewed each component using a top to bottom approach. This starts from customer requirements and extends through to motor selection, gearbox design, and pinion output torque.

Figure 3: The dual gearbox system meshed and preloaded to our 55SSV testing turntable.

DUAL PINION DRIVE TURNTABLE IMPLEMENTATION:

After validating the design, manufacturing the individual components, and completing the full assembly, we moved the drive system to our testing bay. There, it was integrated with our custom designed controls. The next crucial step was to validate positional accuracy – this was the cornerstone of the entire system.

Leveraging advanced PLC programming and fine-tuning the control parameters, we were able to push the system to its limits. The result? A robust, affordable solution that met the specifications of our customer. Even under load, the system performed at very high standards – handling up to 10,000 lbs with exceptional precision and reliability.

In summary, Carousel USA developed an affordable solution for the client’s self-driving car calibration system, integrating with the existing CUSA 55SSV turntable. The innovative dual-gearbox system, featuring preloaded pinion gears and coupled with a Nord AC motor and Stober gearboxes, ensured exceptional precision and reliability. With a focus on positional accuracy (0.1°) and precision (0.01°), the system handled up to 10,000 lbs under load, meeting the customer’s requirements. The design, built using SolidWorks and refined through advanced PLC programming, was heavily tested and delivered outstanding performance.