HEATED TURNTABLE

Case Study

PROBLEM:

Our client required a dual-zone heated turntable for their polyurethane mold station used in manufacturing intake components. The turntable needed independent temperature control for two regions: 140-170°F for the inner zone and 125-160°F for the outer zone. Additionally, precise speed control was essential, with the outer edge moving at a variable rate of 10-15 inches every 20-25 seconds, equating to 0.06-0.1 RPM. The system had to ensure uniform heating and consistent rotation to maintain optimal molding conditions while allowing for process flexibility.

SOLUTION:

Carousel USA engineers designed a custom turntable featuring a 1/2 inch aluminum top surface, heated in two distinct zones for precise temperature control. The inner zone was powered by 32 high-efficiency 600W strip heaters, while the outer zone utilized 16 450W strip heaters. To increase efficiency, protective heat insulators were placed beneath the aluminum surface, ensuring heat was directed upward rather than dissipating downward. Additionally, a custom slip ring was integrated to reliably distribute the substantial power required to operate the heating elements, ensuring consistent performance.

Figure 1: Custom slip ring (left) and strip heaters are fastened to the underside of all top panels (right)

HEATED TURNTABLE FEATURES AND

SPECIFICATIONS:

- Turntable Velocity: Variable 0.06-0.1 RPM

- Top Surface: 1⁄2” 6061 Aluminum Plate with 3” rolled angle back stop

- Load Capacity: 1,300 lbs. Distributed, Rated for continuous use

- Top Surface Heating:

- Inner Zone: Variable adjustment range 140-170°F

- Outer Zone: Variable adjustment range

- Turntable Slip Ring: 32 Circuits

- 12 x 25A @ 230VAC

- 8 x 1A @ 24VDC

- 12 x RTD Signal

- Controls: CUSA Custom Control UL508A Listed

- Momentary and latching modes

- Adjustable RPM Control on front panel

- Electrical Requirements: 200-240VAC, 3Φ, 126A

Figure 2: Installation of the heated turntable with slip ring mounted in the center point

DESIGN PROCESS:

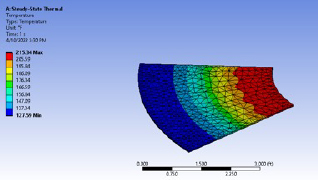

The custom heated turntable was designed using SolidWorks 3D CAD software for mechanical modeling and heating simulation software for precise heat transfer analysis. Accurately sizing and selecting the strip heaters was critical to ensuring thermal efficiency and preventing excessive electrical costs. The heat transfer simulation accounted for both conduction, as heat from the strip heaters was transferred through the aluminum surface, and convection, as the turntable’s rotation exposed it to ambient air, leading to heat loss. Seasonal variations were also factored into the design—higher ambient temperatures in summer reduce heater workload, whereas colder winter conditions increase electrical consumption to maintain target temperatures.

By leveraging our expertise in simulation and engineering design principles, we developed a system that adapts to environmental changes while maintaining energy efficiency. In addition, each component underwent a top to bottom review, from customer requirements to strip heater selection, gear motor sizing, and slip ring integration. This ensured a well engineered and reliable solution.

Figure 3: Screen shot from the heat transfer simulation validating that we would be able to meet or exceed the desired temperatures

HEATED TURNTABLE IMPLEMENTATION:

After completing the design phase, detailed drawings were released to our manufacturing team specifically for fabrication and assembly. After that, the heated turntable underwent a rigorous testing phase, where it was seamlessly integrated with our custom designed controls. In addition, a critical step was validating that the system could achieve the required temperatures under real-world conditions. Through advanced temperature programming and fine-tuning of controls, we successfully ensured the turntable heater system significantly met all performance requirements.

In conclusion, Carousel USA delivered a reliable and efficient solution for the client’s heated polyurethane mold station, significantly improving their manufacturing process. By maintaining precise mold temperatures, the system reduces the need for frequent temperature checks, streamlining operations and enhancing overall productivity.