ROTATING LOCKOUT PIN FOR A MANUALLY OPERATED TURNTABLE

Case Study

PROBLEM:

Our client required a manually operated turntable for their 19-foot antenna with a locking mechanism capable of securing the turntable at precise 10° intervals— without the use of motors or electronic components. This project presented several engineering challenges, primarily due to extreme environmental conditions.

The system was to be deployed in a coastal region, where exposure to salt fog posed a high risk of corrosion and material degradation. Additionally, the solution needed to withstand strong coastal winds up to 100mph and extreme weather conditions while maintaining long-term reliability.

SOLUTION:

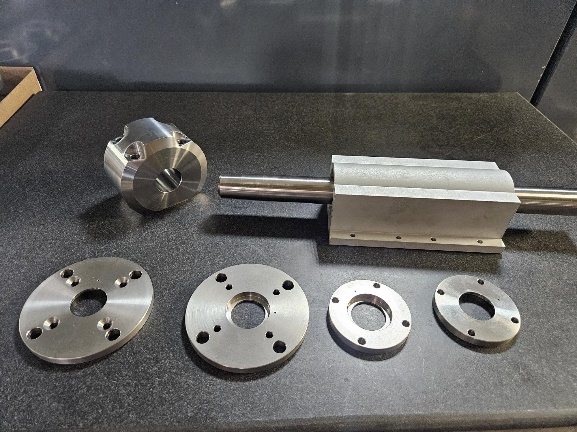

Carousel USA engineers designed a spring loaded lockout pin, precision-machined from 17-4 PH stainless steel. This martensitic precipitation-hardening alloy was selected for its exceptional combination of strength, hardness, and corrosion resistance—critical for withstanding harsh environmental conditions. The components were heat-treated to further enhance their mechanical properties, ensuring long-term durability and reliability.

The system was to be deployed in a coastal region, where exposure to salt fog posed a high risk of corrosion and material degradation. Additionally, the solution needed to withstand strong coastal winds up to 100mph and extreme weather conditions while maintaining long-term reliability.

Figure 1: Machined 17-4PH Stainless steel components ready for fit check prior to heat treating.

FEATURES AND SPECIFICATIONS:

- Turntable Diameter: 62”

- Turntable Height: 8”

- Positional Indexing: 10°

- Positional Precision: ± .04°

- System Weight: 3,100lbs

- Load Capacity: 15,000 lbs. Distributed

- Remote actuation control

- Remote grease line for servicing

- Environment: 5% Salt spray solution no less than 30 days without freshwater washdown

DESIGN PROCESS:

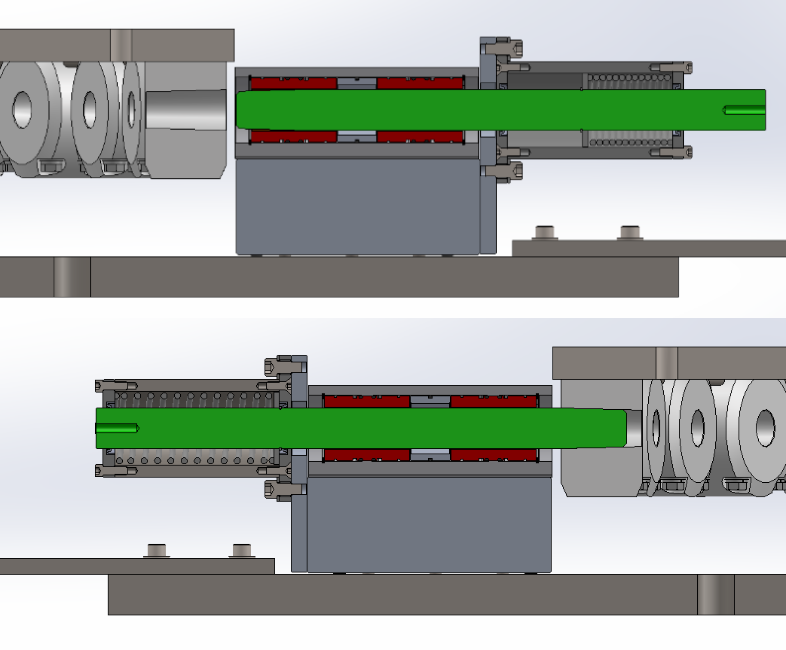

The lockout system was designed from the ground up, leveraging our experience with linear shaft bearings while carefully accounting for turntable runout in the vertical and horizontal directions. Achieving a precise and reliable locking mechanism required a deep understanding of how these components interact under real-world conditions, particularly when dealing with minor inconsistencies in the manually operated turntable’s rotation.

To refine our design, we utilized SolidWorks for both CAD modeling and CAE simulation, allowing us to evaluate different design iterations efficiently. Through virtual testing, we analyzed factors such as load distribution, stress points, and potential wear over time. This iterative process enabled us to fine-tune the system, ensuring it met the necessary strength and durability requirements.

Figure 2: The lockout pin system in the design stage pictured engaged (top) and disengaged (bottom).

Figure 3: ATP (Acceptance Test Procedure) of our final assembly prior to shipment with 8,250lbs of test weight.

CHALLENGES:

Adjustability was essential for assembling the system due to fabrication constraints. Tolerances always play a role, and when multiple components must align precisely, achieving a proper fit can be challenging. Built-in adjustments helped streamline both initial and final assembly, ensuring a smooth process and a reliable system in the end.

Figure 4: Images showing how adjustability was built in using machined components and a series of jack screws and jam nuts to achieve smooth actuation.

ASSEMBLY procedure was a critical aspect of the final assembly by securing each locking block to the pin. This step required close attention and precise shimming to achieve the correct fit and finish. Even slight variations in component deflection could affect alignment, making fine adjustments necessary. By incorporating built-in adjustability and shimming techniques, we were able to compensate for these variations, ensuring that each connection was secure and functioned as intended. This approach simplified and improved the overall quality and reliability of the system.

The overvoltage protection circuit will cut off (float) the motor, quickly stopping the regeneration and voltage surge. Once the motor is floating, the voltage accumulated in the controller’s capacitor will decay. When the voltage goes level below the overvoltage threshold, the transistors reactivate. Because the power transistors disconnect, there is no braking taking place. The motors are freewheeling while coasting or braking, and the internal electronics will not be damaged.

Figure 5: Control lever final assembly (left) and spring loaded pin housing (right).

SUMMARY:

This manually operated 19ft antenna turntable presented a valuable learning experience. It needed to endure harsh coastal conditions, including salt fog, 100 mph winds, and extreme weather, while ensuring long-term reliability. Our engineers designed a high-strength, spring-loaded lockout pin from 17-4 PH stainless steel for its corrosion resistance and durability. The pin is actuated by a dual control lever system with push-pull cables, integrated with a proven slew bearing turntable design and protected by a corrosion-resistant coating.

Using SolidWorks for CAD modeling and simulations, we optimized load distribution and durability. Key features include a 62” diameter, 10° positional indexing, 15,000 lb load capacity, and remote actuation. The assembly process required precise adjustments, like jack screws and shimming, ensuring alignment and smooth operation for reliable performance in extreme conditions.