LIFTING TV SCREEN

Case Study

CONCEPT:

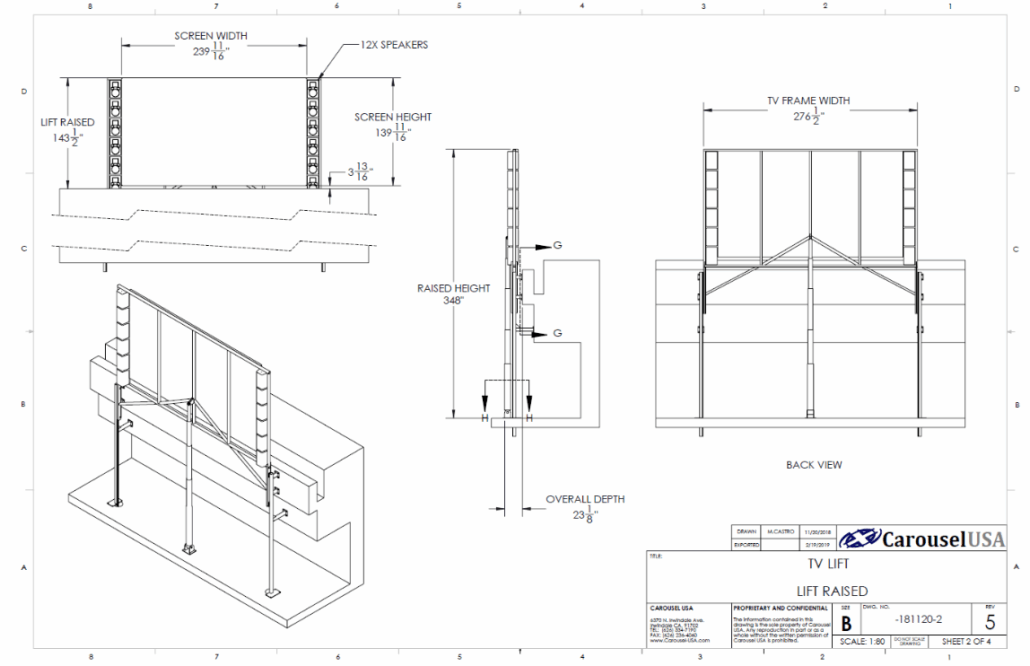

We had a customer seeking a large 23’ x 12’ outdoor lifting media wall that is composed of (84) 14’’ Planar LED displays and (12) 250 Watt JBL speakers. They requested the lifting tv screen to be specifically installed in a Bel Air home on the backside of an infinity pool.

The system was to be deployed in a coastal region, where exposure to salt fog posed a high risk of corrosion and material degradation. The solution also needed to withstand strong coastal winds up to 100mph and extreme weather conditions while maintaining long-term reliability.

PROBLEM:

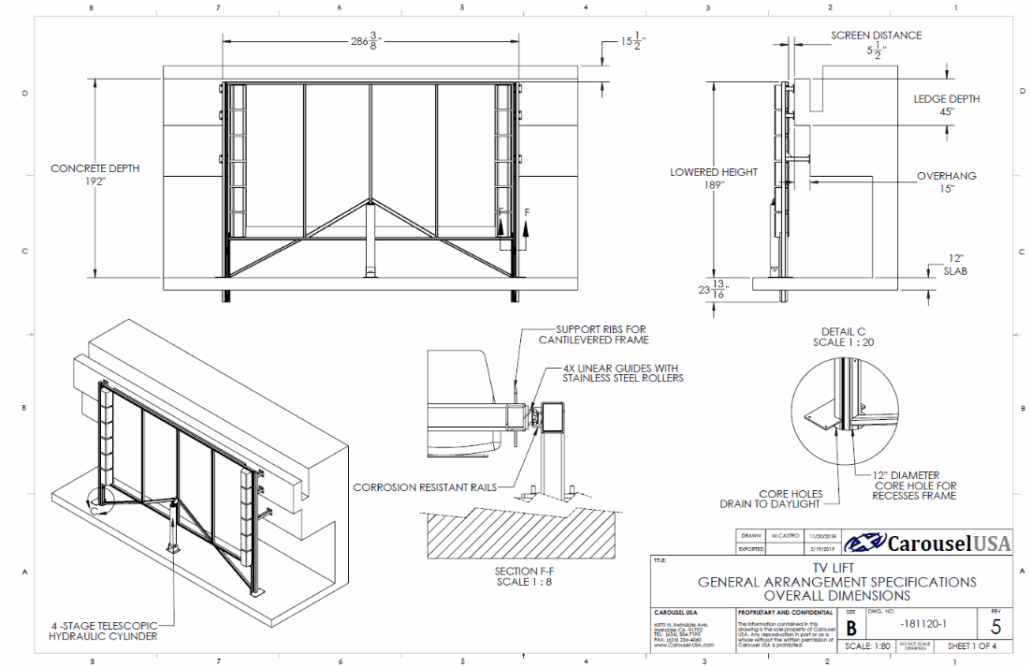

Designing a robust lifting mechanism that could safely lift and lower 3,000 LB reliably. Additionally, installing a large vertically lifting platform on the backside of an uneven hillside wall was going to be a challenge.

SOLUTION:

Linear elevator rails were selected to guide the lifting tv screen frame. They were tied into a specifically designed & fully adjustable mount. The mounts allowed us to precisely adjust the guide system on the backside of a concrete wall. Additionally, our designers had to take environmental considerations in mind and ensure that the lift system would sustain during wind events. The use of FEA analysis played a significant role in designing the lifting system. It would prove to meet our specific environmental loading conditions. However, the lift was designed with an anemometer which indicated wind speed to the controller and moved the lift to a safe and lowered position when the wind speed exceeded 20 mph.

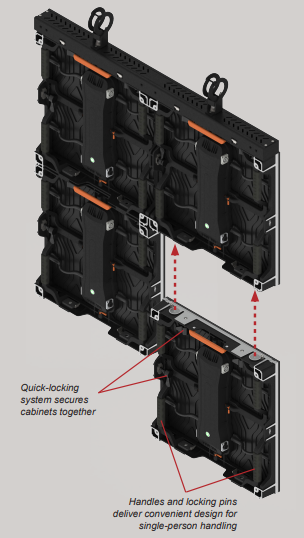

Our engineers worked with architects and media wall specialists to develop the frame which housed all of the electronic media devices. The LED displays were housed in structural steel. They were tied in with unique mounting points specifically made for easy installation and removal of screens.

FEATURES AND SPECIFICATIONS:

Overall dimensions: 23’ x 12’

Load capacity: 3,000 LB

Lifting tv screen time: 30 seconds

Travel: 157’’

Electric actuated pivoting lid

Lift actuation: 4-stage hydraulic cylinder with 2 HP HPU system

Controls: Custom controller with integrated E-stop and anemometer sensor, UL508A Approved

IMPLEMENTATION:

Our team used a crane to hoist our equipment over the hillside. We carefully mounted and adjusted the lifting system onto the vertical hillside wall. It was challenging, but all plans worked accordingly. We ended up with a successful lifting tv screen installation. Subsequently our customer could not have been more satisfied.