DATA CENTER TURNTABLE

Case Study

ABSTRACT:

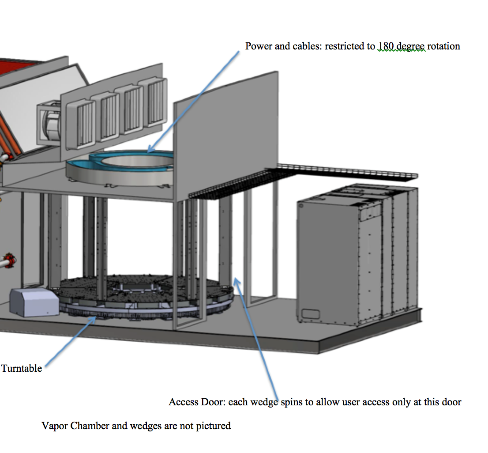

Our customer Vapor.io, was in need of a turntable to rotate a data center rack system that would be installed in shipping container- like cell called a “vapor chamber”. It would house 150 kW of IT equipment for stable, long-term operation. Operators can deploy upwards of 15,000 CPU cores in a 2.88 m (9.45-foot) diameter footprint.

HOW THE DATA CENTER TURNTABLE WORKS:

The unique shape and airflow design of the Vapor Chamber makes it possible for data center operators to deploy an unprecedented level of compute and data storage resources in a cost- and space-efficient way, in a variety of locations

The Vapor Chamber provides physical separation between tenants, with up to 24 tenants per Chamber

The Vapor Chamber can be deployed in standard data center environments but also non-standard office

or retail space, or remote outdoor enclosures such as equipment sheds at the base of cell towers, without the

need for special cooling systems.

An operator controls the motion and direction of the platform

PROBLEM:

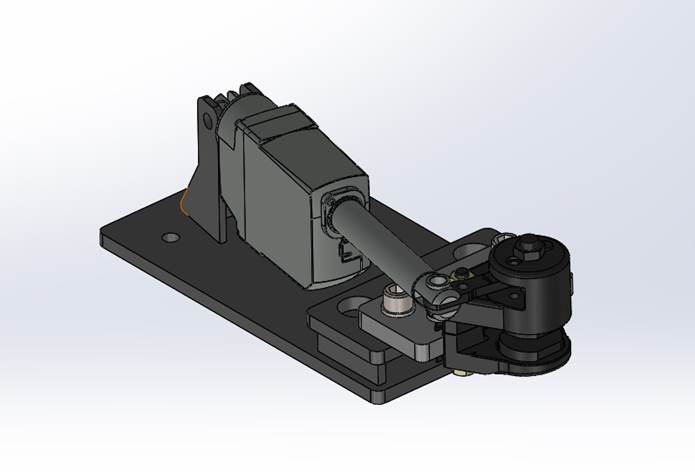

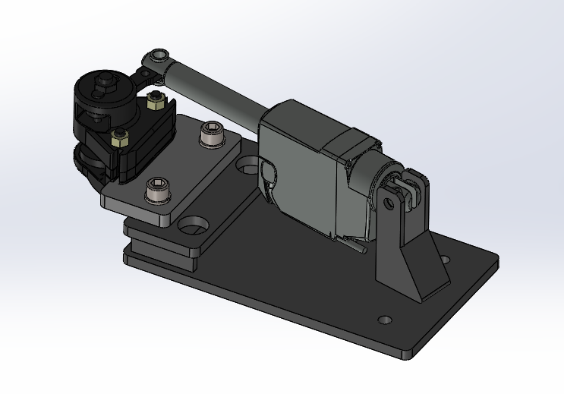

The data center turntable’s standard pin-gear drive backlash was going to pose a problem for the server rack operators since they would be rolling server racks on and off the turntable. No problem, just add a shot pin to the system to lock up the turntable, right? The slight jolt of the shot pin engaging the turntable could disrupt the hard drives with spinning discs, so Carousel USA had to come up with a rotational locking system that operated smoothly without any abrupt movements to the turntable. Additionally, Vapor needed custom structures and components that required custom tooling and developed for repeated manufacturing settings.

DATA CENTER TURNTABLE SOLUTION:

Carousel-USA engineers utilized the running rail, a flat ring that sandwiches the drive pins, as a large brake caliper and designed an electromechanical braking system. The mechanical brake caliper was leveraged by a powerful linear actuator and was designed to squeeze the running rail on any point, 360°, smooth and seamless when the turntable came to a halt. Our engineers also designed custom tooling for Vapor’s one-off storage rack system from sheet metal. The details were meticulously included onto the 3D CAD models using Solidworks, and seamlessly transitioned to our fabricators.

FEATURES AND SPECIFICATIONS:

Turntable Diameter: 114’’

Turntable Height: 8’’

Speed and Position: 0.1-0.3 RPM, 180° movements + 6 stops

Data Center Turntable Load capacity: 20,000 LB distributed

Accuracy: ± 0.05°, at infinite stopped positions

Wilwood manual single piston aluminum caliper

Linak 500 LB linear actuator

Controls: Custom controller with face mounted controller speed controller and E-stop, with Modbus RTU master and slave, UL508A Approved

IMPLEMENTATION:

The brake caliper system was tested for over 5,000 cycles to ensure the proper amount of clamping force was being applied to the running rail as well as confirming smooth and robust holding of the turntable. The running rail was also machined as an assembly to ensure that it spun true with a total indicated runout of .004’’. Like your vehicles rotors, it was imperative that rotor rotated true to the center axis to ensure smooth and confident operation for the operator.

RESULTS:

A robust, cost-effective solution that not only met but exceeded the demanding specifications of our customer. The sheet metal server rack components fit up neatly to the electronic equipment, and the brake system held the data center turntable smooth and firm when the vapor chamber was in full operation.

The overvoltage protection circuit will cut off (float) the motor, quickly stopping the regeneration and voltage surge. Once the motor is floating, the voltage accumulated in the controller’s capacitor will decay. When the voltage goes level below the overvoltage threshold, the transistors reactivate. Because the power transistors disconnect, there is no braking taking place. The motors are freewheeling while coasting or braking, and the internal electronics will not be damaged.