DEVIL’S WHEEL ROTATING PLATFORM

Case Study

ABSTRACT:

We had a customer looking for an amusement ride type of turntable called a devil’s wheel. A devil’s wheel, also known as the Teufelsrad, is a rotating platform that spins riders off. It’s a popular attraction at the Munich Oktoberfest.

HOW IT WORKS & HISTORY:

- The rotating platform starts spinning slowly and increases speed

- Riders sit or lie on the platform and use centripetal forces to stay on

- Riders who lose their balance slide off the rotating platform

- Riders usually hit a cushioned wall

- An operator controls the motion and direction of the rotating platform

- Spectators watch the riders as they try to stay on

- The Teufelsrad has been part of Oktoberfest since 1908

- The Teufelsrad is a simple and ingenious concept that doesn’t use modern technology

SOLUTION:

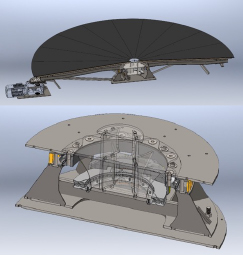

Our engineers utilized a modern heavy duty brake system, coupled to the center bearing of the turntable. The brake system operates with a manual brake hand lever via hydraulic master cylinder. The brake system components were selected from a domestic supplier that had production parts on the shelf, which lowered cost and lead time. Integrating the brake system into our rotating platform was done using Solidworks 3D software, allowing us to squeeze the mammoth caliper and rotor into the compact center bearing assembly. After all, we solved the turntable’s motor overvoltage problem with a custom designed controller, featuring a regeneration system.

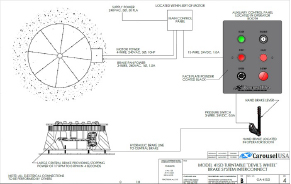

The overvoltage protection circuit will cut off (float) the motor, quickly stopping the regeneration and voltage surge. Once the motor is floating, the voltage accumulated in the controller’s capacitor will decay. When the voltage goes level below the overvoltage threshold, the transistors reactivate. Because the power transistors disconnect, there is no braking taking place.

Images 1-3: Section views of the Devil’s Wheel turntable system and central brake system, Main Control Panel with overvoltage protection circuit.

FEATURES AND SPECIFICATIONS:

- Turntable Velocity: 19 RPM

- Turntable Load capacity: 4,500 LB

- Acceleration: 0-17 RPM in 5 seconds

- Deceleration: 17-0 RPM in 3 seconds

- Wilwood 16’’ cast iron brake rotor with billet aluminum hat

- Wilwood 6 piston billet aluminum caliper

- Wilwood handbrake pull lever

- 10 HP Nord motor with helical bevel gearbox

- Controls: Custom controller with face mounted speeds and E-stop, with overvoltage protection circuit, UL508A Approved

IMPLEMENTATION:

The brake rotor hat adapter was carefully machined as an assembly to ensure that the rotor spun true with a total indicated runout of .002’’. Like your vehicles rotors, it was imperative that rotor rotated true to the center axis to ensure smooth and confident operation for the devils wheel operator. After validating the design and completing the full assembly, we moved the devil’s wheel rotating platform to our testing bay. There, it was rigorously tested and measured against the target specifications as well as durability and ease of use. This is the cornerstone of all Carousel USA systems.

Image 5: Devils Wheel motion control system overview and interconnect

RESULTS:

A robust, cost-effective solution that met but expectations of our customer. The operator controls were simple to use and controlling the motion was extension of body, performing every start/stop, accel/decel, and change in direction without a hitch.