LIFTING ROTARY TURNTABLE

Case Study

PROBLEM:

Our client required a 10-foot diameter lifting rotary turntable capable of rotating and lifting up to 35,000 lbs. The unit was to be installed inside a large furnace at their glass manufacturing facility, requiring all components to withstand temperatures up to 180°F. To meet performance standards, we designed the turntable with a minimal vertical deflection requirement of just 0.01 inches. Additionally, lift position feedback was a key requirement to ensure precise operation.

SOLUTION:

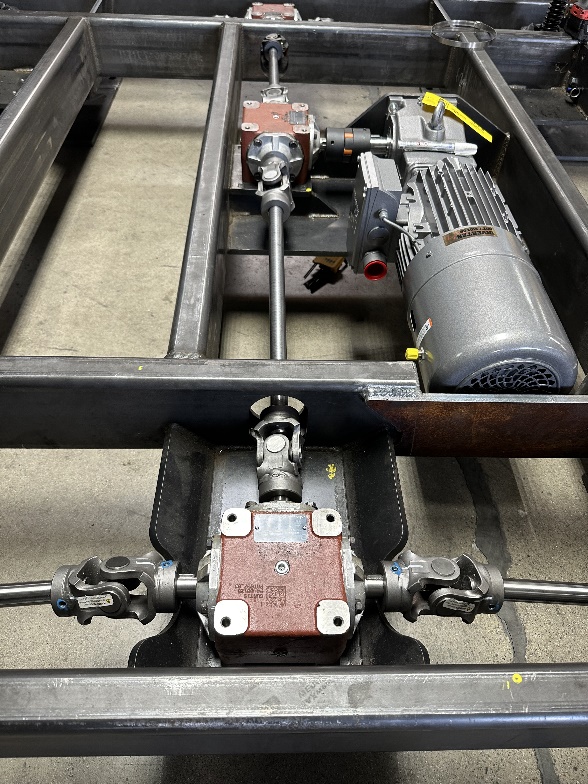

Carousel USA engineers designed a high performance rotary turntable featuring a rigid platform coupled to four 10-ton Acme jack screws. Each screw driven by a series of gearboxes and a 3 HP high torque, continuous duty gear motor. This design ensures perfect synchronization of the jack screws, allowing the rotating platform to move smoothly while maintaining a flat and level position.

Figure 1:

Gearbox system and Stober Gearboxes fastened to a machined base plate for precision axial alignment of input shafts

FEATURES & SPECIFICATIONS:

Turntable Velocity: Variable 0.35-2.0 RPM

Top Surface: 3⁄4” ASTM A36 Steel Plate

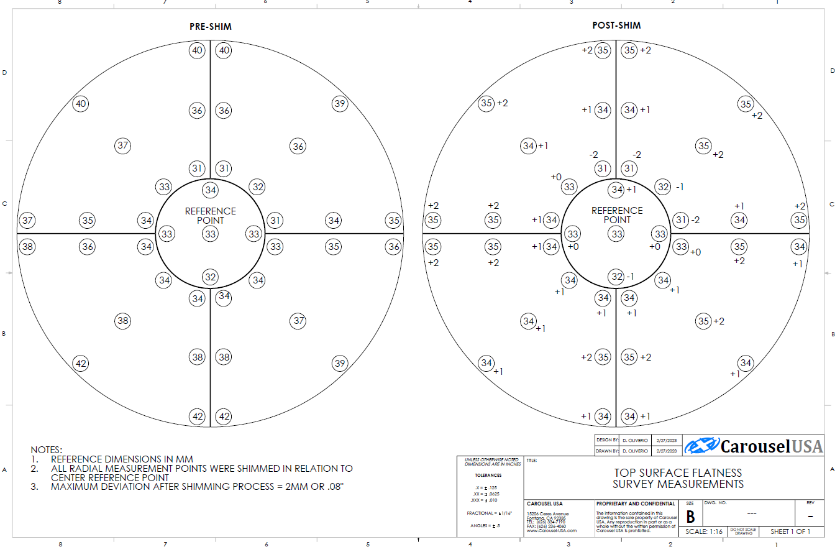

Flatness: ±1/8”

Load Capacity: 35,000 lbs. Distributed, Rated for continuous use

Lift Travel: 21.5”

Lift Platform Velocity: 3in/min (7.2min for 21.5”)

Controls: CUSA Custom Control UL508A Listed

Digital Readouts

Rotary Turntable Speed: Accuracy ±0.05 RPM

Rotary Turntable Height: ±0.0625”

Outside Temperature

Inside Temperature

Adjustable RPM Control on front panel

Directional Control

Electrical Requirements: 480VAC, 3Φ, 15A

Drive system (top) and full component assembly testing (bottom)

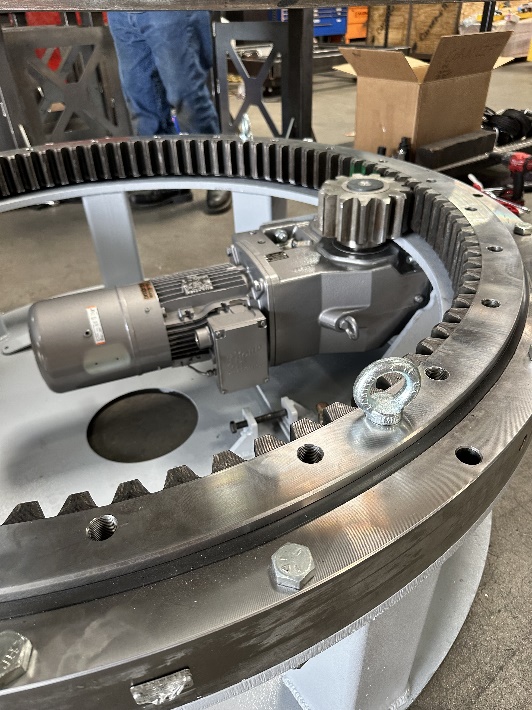

Figure 1 & 2: Turntable Drive System with 3HP gear motor and internally geared slew bearing

Figure 3: Flatness survey process (left) results (right)

DESIGN PROCESS:

Figure 1:

Gearbox system and Stober Gearboxes fastened to a machined base plate for precision axial alignment of input shafts

The custom lifting rotary turntable was designed using SolidWorks 3D CAD software for mechanical modeling, along with advanced simulation tools for precise finite element analysis (FEA). This approach allowed us to evaluate structural integrity, identify areas where deflection exceeded our strict 0.01-inch requirement, and refine the design accordingly. By iterating through multiple design optimizations, we ensured that the turntable met all performance criteria while maintaining reliability under load and high temperature conditions.

Figure 4: Limit switch control of the turntable height is very important to protect components from over travel

IMPLEMENTATION:

To meet the requirements of a glass manufacturing facility, Carousel USA designed and built a custom 10-foot diameter lifting rotary turntable capable of rotating and lifting up to 35,000 lbs. The unit was engineered to operate inside a large furnace, requiring all components to withstand temperatures up to 180°F while maintaining a minimal vertical deflection of 0.01 inches. Our solution featured a rigid platform supported by four synchronized 10-ton Acme jack screws, driven by a series of gearboxes and a 3 HP high torque, continuous duty gear motor. Designed for precision and durability, the turntable included variable speed control (0.35–2.0 RPM), digital readouts for turntable speed and height, and a UL508A-listed custom control system.

To ensure flawless performance, we conducted a rigorous assembly and testing phase, verifying synchronization of the jack screws, load distribution, and system responsiveness. Using Solid-Works 3D CAD software and finite element analysis (FEA), we optimized the design to ensure structural integrity, smooth operation, and compliance with strict performance criteria. The result was a high performance & reliable lifting turntable!