PROJECT LOON - CENTER PIVOT TURNTABLE

Case Study

ABSTRACT:

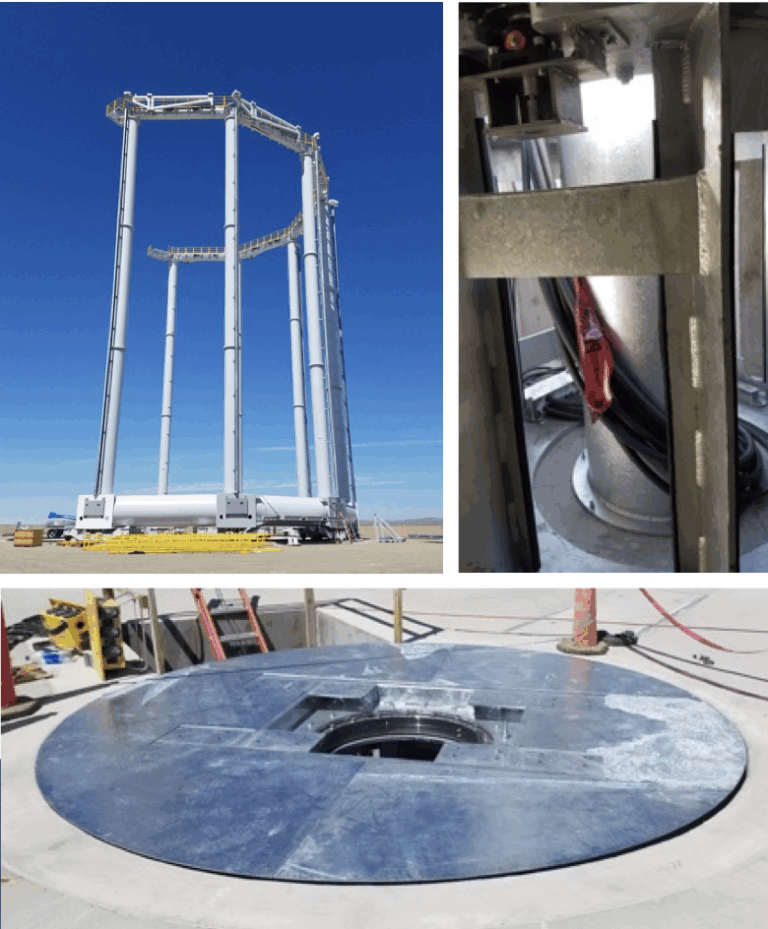

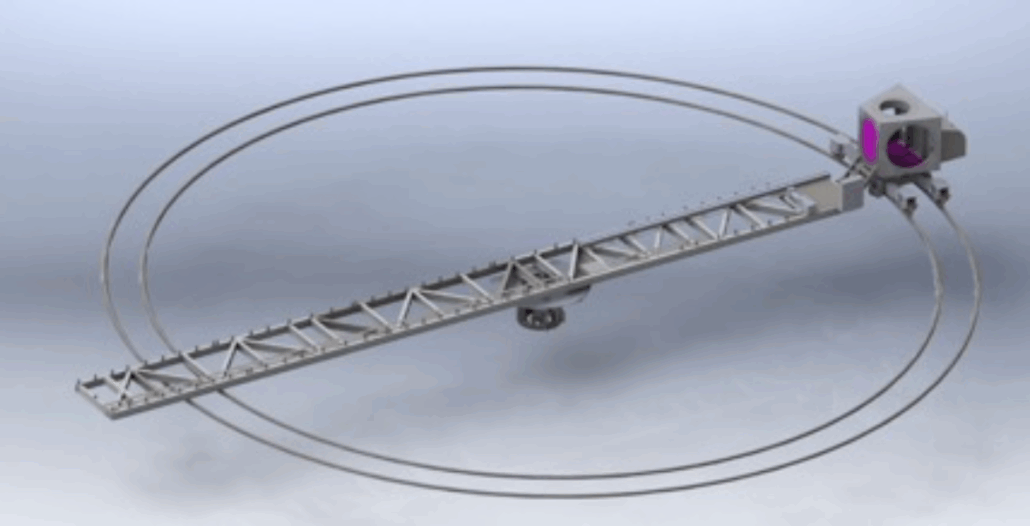

Project Loon, a Google-backed project that used high altitude ballons that act as a “floating cell tower”, to provide internet access and cell signal to remote areas. Our customer, X- Development, awarded Carousel USA the task of building the center pivot turntable for the launch station.

HOW LOON WORKED AND GOALS:

The balloons floated in the stratosphere at altitudes of 11–16 miles high

Users connected to the network using an antenna attached to their building

The signal traveled from balloon to balloon, then to a ground station, and then to internet

Loon’s goal was to provide internet access to rural and remote areas

It could have helped developing countries avoid expensive underground infrastructure

Loon was also used to help with environmental crises, such as flooding in Peru and Hurricane Maria in Puerto Rico

PROBLEM:

The turntable was acting as the center pivot to the ground launch station. Not only did the turntable have to keep the massive ballon housing structure tied down, but provisions for the balloon utility bridge (10) 350MCM power cables (up to 3,000 Amps at 600V!), Fiber optic cables, and 2’’ gas pipes for helium, all having 720° of rotation.

SOLUTION:

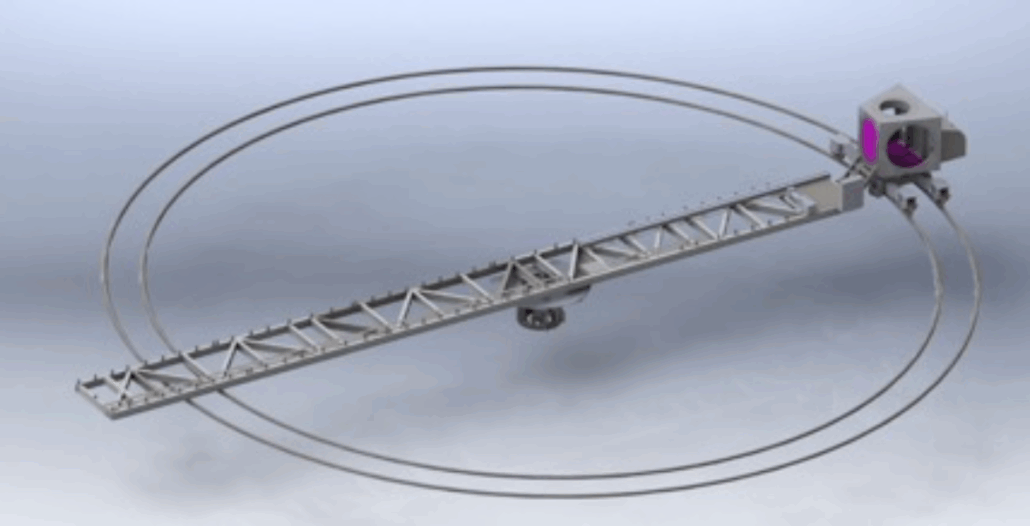

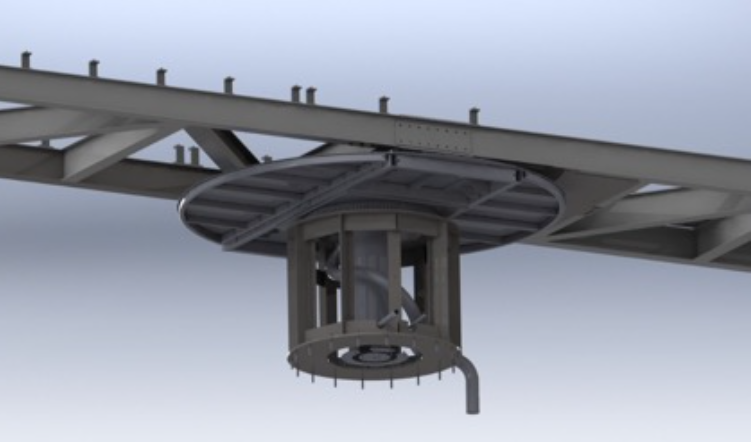

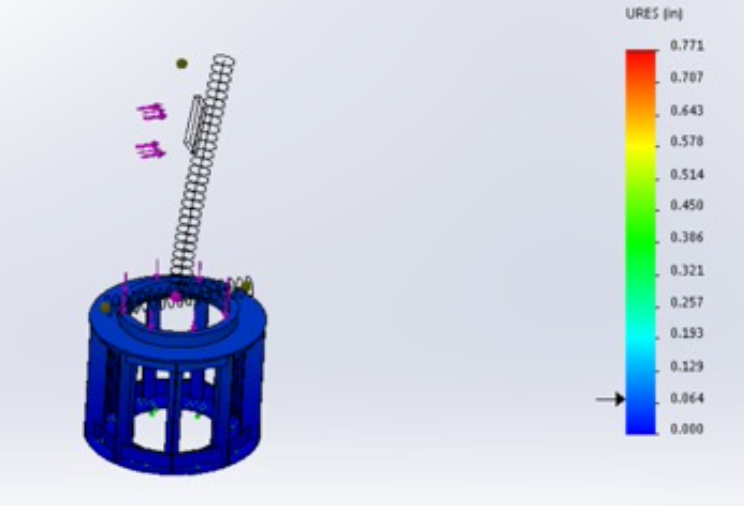

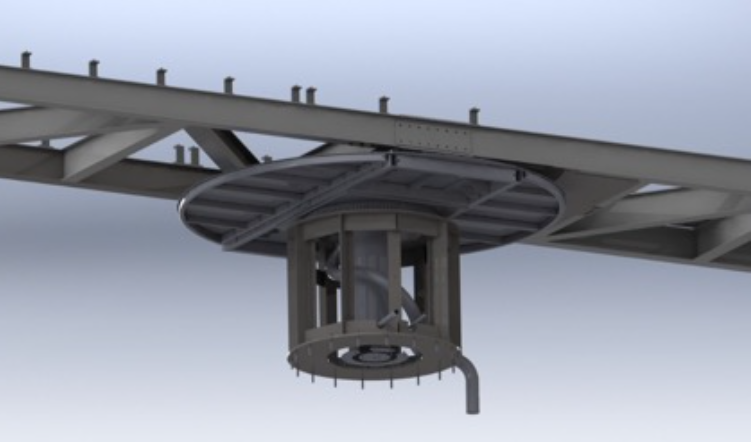

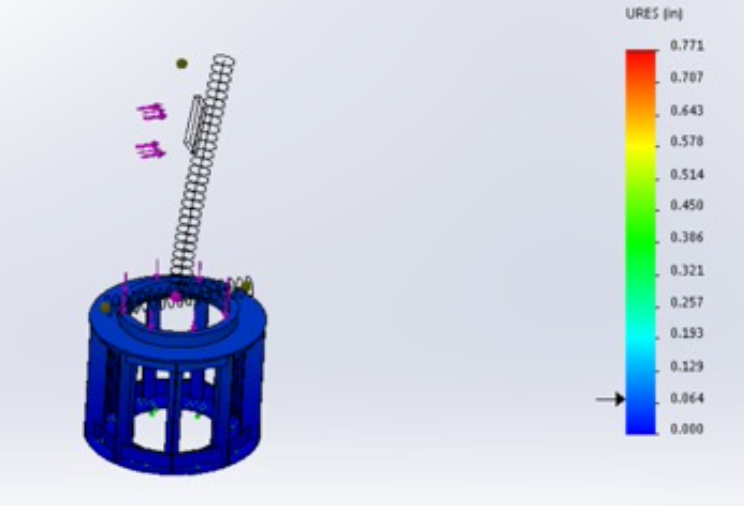

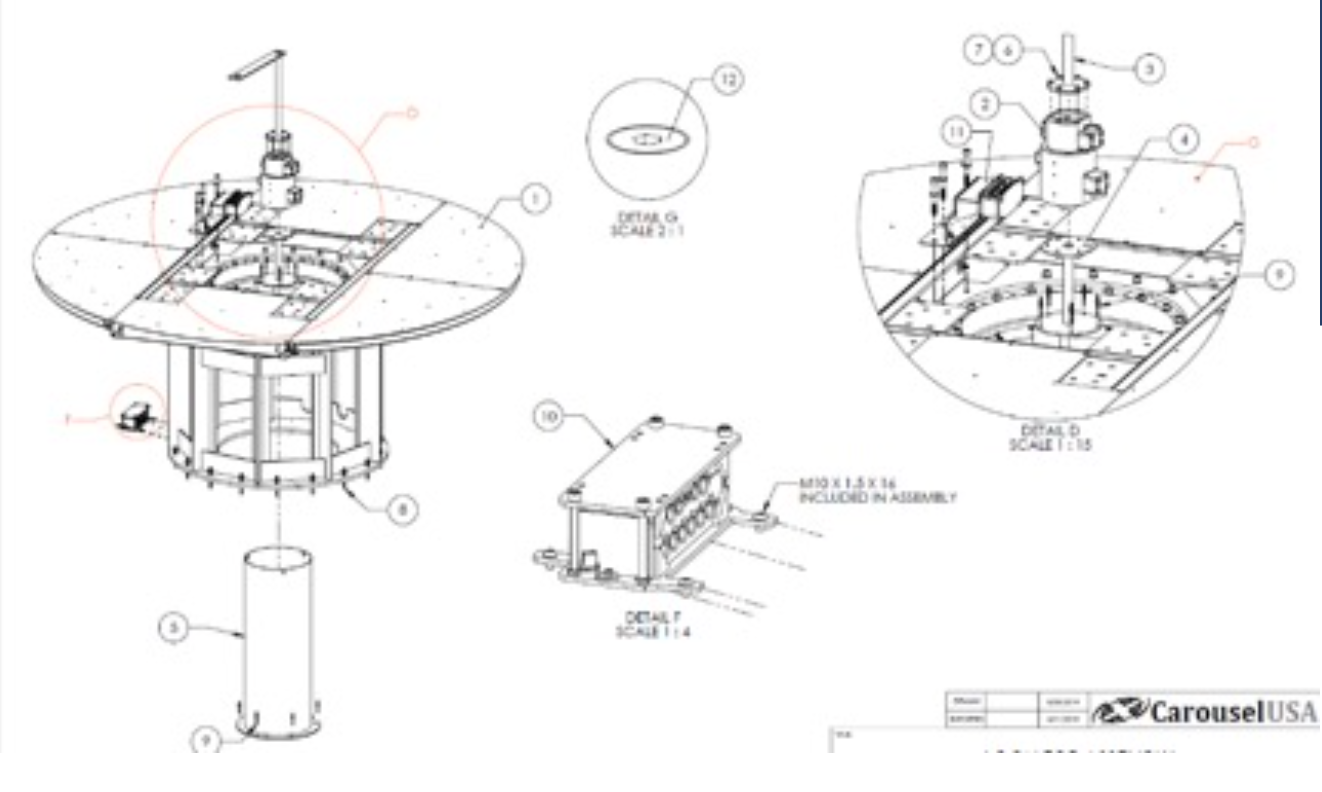

Our engineers developed a simple yet effective cable management system that allowed the large cables to move freely within the center bearing area in a coiled, vertical fashion. This low tech yet effective solution eliminated the need for cable chain systems that required enormous amounts of space, a whole host of small moving parts, and lastly long lead times and unnecessary addition costs. This in-house solution also utilized a robust steel structure and slew bearing, custom designed rotary joints for gasses and fiber optics, and positional feedback sensors. The pivot turntable system was designed with Solidworks 3D software, allowing us to optimize all spatial constraints and validate the design, reducing costs and potential issues on the field.

PIVOT TURNTABLE FEATURES AND

SPECIFICATIONS:

Turntable Diameter: 14’

Turntable Load capacity: 60,000 LB downward, 10,000 LB upward, 20,000 LB horizontal

Rotation: 720°

Cable management system: (10) 350MCM cables, UHMW strain relief blocks

Rotary Joint: (4) Tactical fiber optic cables, (4) 2’’ Schedule 40 pipes

Passively driven

Rotation sensors: (2) Push/pull encoders for pivot turntable positioning

IMPLEMENTATION:

The cable management system was first developed at 1:20 scale to validate the functionality of the design. Our engineers tested the scale model on a bench for over 40 hours continuously and carefully fine-tuned the design on strain relief points, cable orientation, and cable length. Once the test model satisfied our test requirements, we skillfully executed the build plans and fabricated the full-size turntable assembly. The entire utility system was tested at full scale and then once again upon final installation.

RESULTS:

A reliable, cost-effective installation that not only met but exceeded the demanding specifications of our customer. Carousel’s pivot turntable with custom cable management system proved to be successful by its simple design and fine- tuned components that worked harmoniously with the entire system.