SHOT PIN LOCKING TURNTABLE FOR TRUCKS

Case Study

PROBLEM:

This case study involves a previously installed turntable at a loading dock. It would regularly see large trucks doing loading/unloading processes while parked directly on top of the turntable. The truck turntable initially aligned the semi-trucks to the loading bay they wished to use. However, the loading/unloading process and turning of the truck’s wheels could shift the turntable, at times causing un-alignment with the loading bay.

SOLUTION:

Our engineers designed an add-on shot pin system. This would lock the truck turntable in place using large & multiple shot pin receivers welded underneath the top surface. This solution, however, required precise confirmation that the shot pin was aligned with the receiver to avoid the shot pin damaging the receivers or other surrounding equipment.

Shot pin aligned with receiver, underneath the top surface of the truck turntable.

DESIGN PROCESS:

Due to the critical nature of shot pin alignment the engineering team decided to use proximity sensors with a flag placed at each loading bay locking position, in addition to the existing turntable motor encoder. This provided two critical checks. It ensured the turntable was at the correct rotational angle for each shot pin receiver as a prerequisite before the shot pin engaged.

Furthermore, proximity sensors were placed on the shot pin itself. This give transparency on whether the shot pin was retracted or extended at any point in the process. This was necessary as a check to ensure that the shot pin was fully retracted prior to any turntable movement. It also prevented damage to the receivers or other nearby equipment.

IMPLEMENTATION:

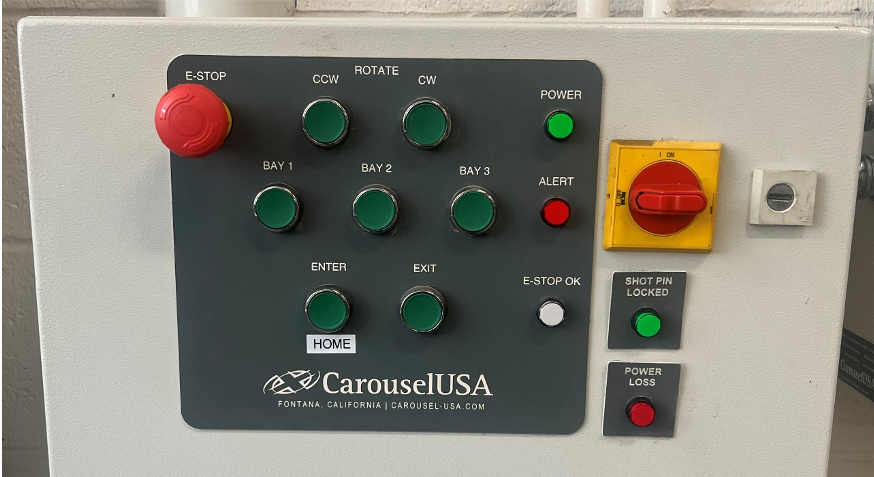

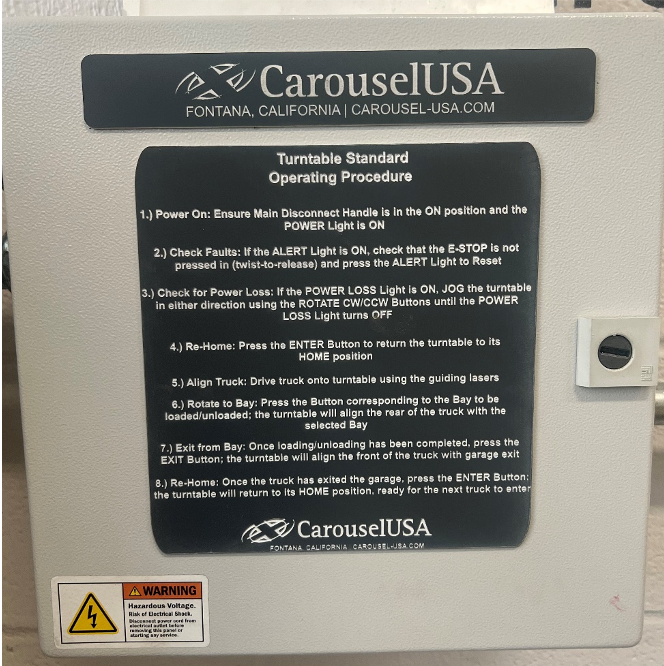

During implementation, it was realized that, although the shot pin had fully engaged and the truck turntable was locked, there was no physical indication of such behavior. To remedy this, an indicator light was added to the face of the control panel. It tied directly to the “shot pin extended” proximity sensor. It was also found that any loss of power would cause the motor encoder to lose its position and prevent the shot pin from engaging. The solution was to add another indicator that would be lit when power was restored following a power loss. A standard operating procedure was listed on the control panel to rotate the turntable a full 360°, which would allow the table to recalibrate and find its correct position.

Figure 2: Control panel door operators with added shot pin locked and power loss indicator lights.

Figure 3: Standard operating procedure placard placed in clear view on door of shot pin control panel, allowing any truck operator to follow best practices and increase effectiveness of turntable and loading dock at large.

SUMMARY:

In conclusion, Carousel-USA engineers recognized a problem which a previous client faced with their turntable. They devised a cost-effective add-on that would still make use of the existing equipment. This system was designed with a focus on safety. They always kept the operator informed of current processes, which ultimately made the loading dock environment much more efficient.